Silicon Steel Laminations: Essential Components for Efficient Electrical Systems

- 获取链接

- X

- 电子邮件

- 其他应用

Silicon steel laminations, also known as

electrical steel laminations, are thin, flat sheets of low-carbon steel

alloyed with silicon—typically 0.5% to 4.5% by weight. This unique

composition grants them exceptional magnetic properties, making them

indispensable in the production of electrical equipment that relies on

electromagnetic induction.

The addition of silicon is critical: it increases the material’s

electrical resistivity, which minimizes eddy current losses— a major

source of energy waste in magnetic devices. Moreover, silicon enhances

magnetic permeability, allowing the material to efficiently conduct

magnetic flux, and reduces hysteresis losses, which occur when the

magnetic field reverses direction.

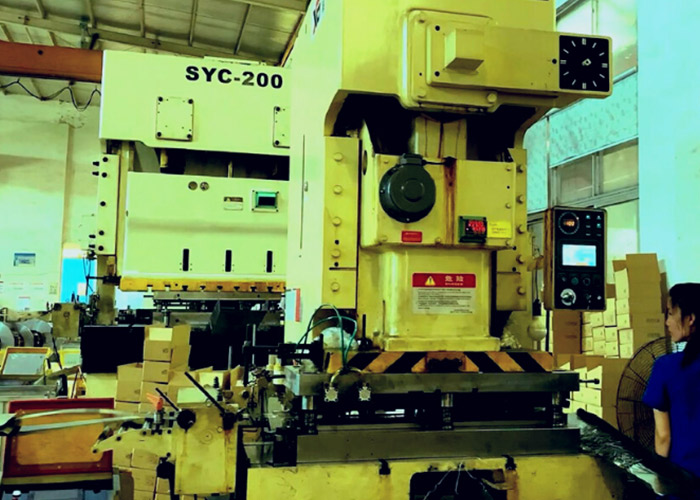

Manufacturing silicon steel laminations involves precise processes. The

steel is first rolled into thin sheets (usually 0.15mm to 0.5mm thick)

through cold rolling, which aligns the metal’s crystalline structure (a

process called grain orientation) to optimize magnetic performance.

After rolling, the sheets are cut into specific shapes (such as

rectangles or E-cores) using laser or punch cutting, ensuring tight

tolerances for seamless assembly.

These laminations are primarily used in the cores of transformers,

electric motors, and generators. In transformers, stacked laminations

form a core that channels magnetic flux between primary and secondary

coils, maximizing energy transfer efficiency. In motors and generators,

they form the stator and rotor cores, enabling the conversion of

electrical energy to mechanical energy (or vice versa) with minimal

losses.

As global demand for energy efficiency grows, the role of

high-performance silicon steel laminations becomes increasingly vital.

Advancements in alloy composition and manufacturing techniques continue

to improve their performance, helping to reduce energy consumption in

power grids, electric vehicles, and industrial machinery—key steps

toward a more sustainable energy future.

- 获取链接

- X

- 电子邮件

- 其他应用

评论

发表评论