Silicon Steel Laminations: The Backbone of Electromagnetic Devices

- 获取链接

- X

- 电子邮件

- 其他应用

Silicon steel laminations, also known as

electrical steel laminations, are crucial components in a wide range of

electrical and electronic devices. Made from silicon steel sheets, these

laminations play a fundamental role in enhancing the performance of

transformers, motors, generators, and other electromagnetic equipment.

Silicon steel is a ferrosilicon soft magnetic alloy with an extremely

low carbon content, typically around 0.08%, and a silicon content

ranging from 0.5% to 4.5%. The addition of silicon to iron brings about

several desirable properties. It significantly increases the resistivity

of the material, which is essential for reducing eddy current losses.

Eddy currents are induced currents that circulate within the core of an

electromagnetic device, causing energy dissipation in the form of heat.

By raising the resistivity, silicon steel laminations minimize these

losses, leading to more efficient operation.

Moreover, silicon addition boosts the maximum magnetic permeability of

iron. High magnetic permeability allows the material to easily magnetize

and demagnetize in response to an applied magnetic field. This property

is vital for devices like transformers, where efficient transfer of

electrical energy between coils relies on the core’s ability to carry

magnetic flux. Additionally, silicon helps in reducing the coercive

force, which is the amount of magnetic field required to demagnetize a

material. Lower coercive force means less energy is wasted in reversing

the magnetization of the core during operation.

The manufacturing process of silicon steel laminations involves multiple

steps. It starts with the production of silicon steel sheets through

either hot rolling or cold rolling. Hot rolled silicon steel laminations

are made by heating the steel billet and rolling it at high

temperatures. Cold rolled silicon steel laminations, on the other hand,

are produced by rolling the steel at room temperature after an initial

hot rolling process. Cold rolling offers better control over the sheet

thickness and surface finish, resulting in higher quality laminations.

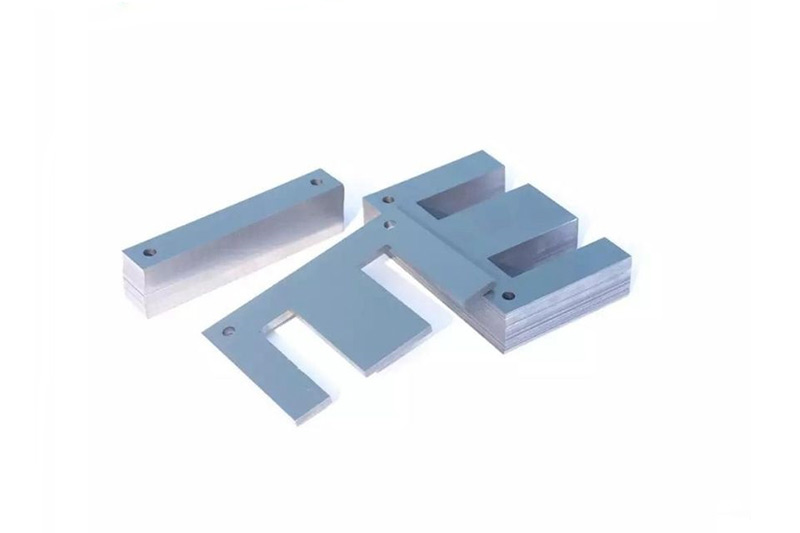

After the sheets are produced, they are further processed. This may

include annealing to relieve internal stresses and improve magnetic

properties, stamping into specific shapes such as the common E and I

shapes for transformer cores, and applying an insulating coating. The

insulating coating is crucial as it prevents the formation of short

circuits between adjacent laminations, reducing the risk of increased

eddy current losses.

Silicon steel laminations find extensive applications in various

industries. In the power industry, they are used in the cores of power

transformers, which are essential for transmitting and distributing

electrical energy at different voltage levels. In the automotive

industry, they are used in electric motors for electric and hybrid

vehicles, as well as in alternators. In the electronics industry, they

are used in small transformers for power supplies in electronic devices.

In conclusion, silicon steel laminations are indispensable in modern

electrical and electronic engineering. Their unique combination of

magnetic and electrical properties, along with efficient manufacturing

processes, makes them the material of choice for applications where high

magnetic performance and low energy losses are required. As technology

continues to advance, the demand for high-quality silicon steel

laminations is expected to grow, driving further innovation in their

production and application.

- 获取链接

- X

- 电子邮件

- 其他应用

评论

发表评论